Robotics in Industry: Automation’s Impact on Manufacturing

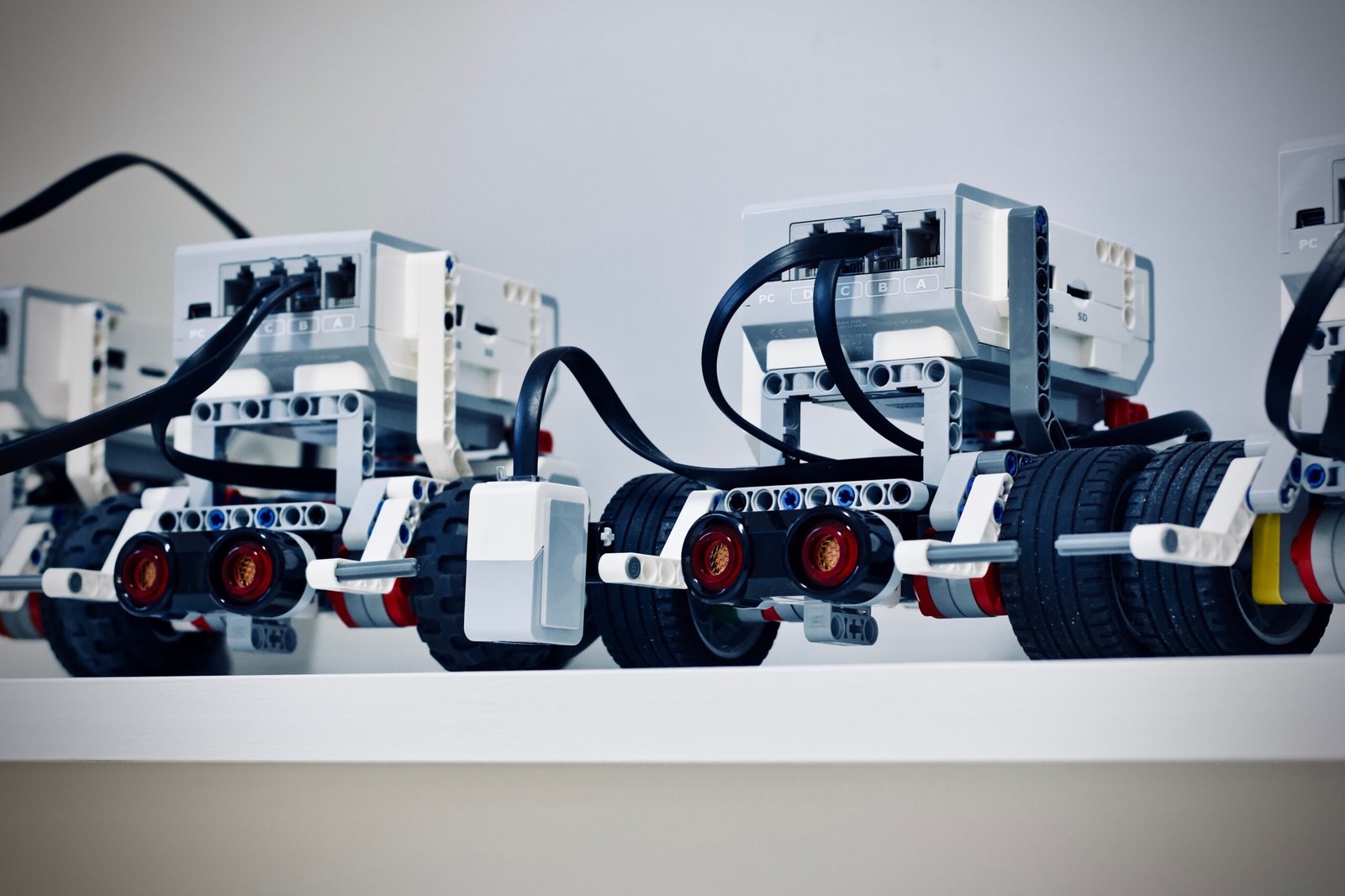

The Role of Robotics and Automation in Modern Manufacturing

In today’s rapidly evolving world, robotics and automation have become integral parts of the manufacturing industry. With their ability to perform tasks with precision and efficiency, robots have revolutionized the way products are made. This blog post will explore the role of robotics and automation in modern manufacturing and discuss their impact on increased efficiency and job displacement.

Increased Efficiency

One of the key benefits of robotics and automation in manufacturing is the increased efficiency they bring to the production process. Robots can perform repetitive tasks with consistent precision and speed, leading to higher productivity levels. They can work 24/7 without the need for breaks, resulting in faster production cycles and reduced downtime.

Moreover, robots can handle hazardous or dangerous tasks that may pose risks to human workers. By taking over these tasks, robots ensure the safety of the workforce and minimize the occurrence of accidents and injuries.

Job Displacement

While the introduction of robotics and automation has undoubtedly improved efficiency in manufacturing, it has also led to concerns about job displacement. As robots take over repetitive and mundane tasks, some workers may find their roles becoming obsolete.

However, it is important to note that the role of humans in manufacturing is not completely eliminated. Instead, the nature of jobs may shift towards more complex and skilled tasks that require human creativity and problem-solving abilities. As robots handle routine tasks, human workers can focus on innovation, product development, and quality control.

Furthermore, the increased efficiency brought by automation can lead to cost savings for manufacturers. This, in turn, can create new job opportunities in other areas of the company, such as research and development, customer service, and maintenance of the robotic systems.

The Future of Robotics in Manufacturing

The future of robotics in manufacturing is promising. As technology continues to advance, robots are becoming more intelligent and capable of handling complex tasks. Collaborative robots, also known as cobots, are designed to work alongside human workers, enhancing productivity and safety.

Additionally, the integration of robotics with other emerging technologies, such as artificial intelligence and the Internet of Things, opens up new possibilities for automation in manufacturing. Smart factories equipped with interconnected robotic systems can optimize production processes, improve product quality, and reduce waste.

While there may be concerns about the impact of robotics and automation on the workforce, it is essential to embrace these advancements and adapt to the changing landscape of manufacturing. By leveraging the benefits of robotics and automation, manufacturers can achieve higher efficiency, improved product quality, and ultimately, greater competitiveness in the global market.